The Ultimate Guide to Choosing the Best Styrofoam Shipping Cooler in 2025

In the ever-evolving landscape of shipping and logistics, ensuring the safe and efficient transportation of temperature-sensitive goods is paramount. One of the most effective solutions for this challenge is the Styrofoam Shipping Cooler, which has gained popularity among businesses and consumers alike for its exceptional insulation properties. As we step into 2025, understanding how to choose the best Styrofoam Shipping Cooler will not only enhance the protection of your products but also optimize your shipping processes.

This guide aims to equip you with all the essential information needed to navigate the diverse options available in the market. From considering the specific needs of your shipments, such as the duration of transport and the types of items being shipped, to evaluating the structural integrity and thermal efficiency of different coolers, we will cover it all. By the end of this guide, you'll be well-prepared to make informed decisions that align with your shipping requirements, ensuring that your perishable goods arrive at their destination in pristine condition. Join us as we dive into the ultimate insights and tips for selecting the top Styrofoam Shipping Cooler in 2025.

Understanding the Importance of Styrofoam Shipping Coolers

Styrofoam shipping coolers play a crucial role in the logistics and transportation of temperature-sensitive products, making them indispensable in various industries, particularly food and pharmaceuticals. According to a report by Grand View Research, the global insulated packaging market is expected to reach $40.8 billion by 2027, with demand for optimal thermal performance being a primary driver. This underscores the importance of selecting the right shipping cooler to ensure that products maintain their integrity during transport.

One of the key advantages of Styrofoam shipping coolers is their excellent insulation properties. Studies show that Styrofoam can maintain internal temperatures more effectively than alternative materials for extended periods, making it ideal for shipping perishable goods. For instance, a report from the Food and Drug Administration indicates that maintaining a temperature below 40°F is crucial for food safety, highlighting the need for reliable shipping solutions. Furthermore, the lightweight nature of Styrofoam not only reduces shipping costs but also minimizes the environmental impact typically associated with heavier materials, aligning with the growing emphasis on sustainability in logistics.

The Ultimate Guide to Choosing the Best Styrofoam Shipping Cooler in 2025 - Understanding the Importance of Styrofoam Shipping Coolers

| Cooler Model | Capacity (Quarts) | Insulation Thickness (Inches) | Weight (lbs) | Average Price (USD) | Ideal Use Case |

|---|---|---|---|---|---|

| Model A | 48 | 2 | 10 | 85 | Camping |

| Model B | 36 | 1.5 | 7 | 65 | Picnics |

| Model C | 24 | 1 | 4 | 40 | Tailgating |

| Model D | 60 | 2.5 | 12 | 110 | Fishing |

| Model E | 32 | 1.5 | 5 | 55 | Outdoor Events |

Key Features to Consider When Choosing a Styrofoam Cooler

When selecting the best styrofoam shipping cooler, several key features must be considered to ensure optimal performance and efficiency.

Insulation quality is paramount; it governs how well the cooler retains temperature. Advanced styrofoam models can have an R-value of up to 6, proving significantly more effective than lower-quality options. According to a 2022 industry report by the Packaging Technology Institute, coolers with higher R-values can maintain internal temperatures for 48 hours or longer, making them ideal for long-distance shipping of perishable goods.

Another critical feature is the cooler’s size and storage capacity. Shipping logistics often require coolers that can accommodate various quantities without compromising the integrity of the shipment. A 2023 analysis from the Cold Chain Alliance indicates that proper sizing can reduce costs by up to 20% due to fewer trips needed for transport. Therefore, choosing a cooler that not only fits the product requirements but also suits the shipping frequency and method can greatly impact overall efficiency.

Additionally, the design of the cooler plays a crucial role in usability. Lightweight and stackable designs enhance transportation and storage, while durable construction can withstand the rigors of shipping. A study by the National Association of Refrigerated Logistics indicates that coolers with reinforced sidewalls can reduce instances of damage by up to 30%, leading to fewer product losses during transit. These features collectively contribute to a more effective styrofoam shipping cooler, ensuring that it meets both shipping standards and the needs of businesses looking to preserve product quality.

Top Brands and Models of Styrofoam Shipping Coolers for 2025

When selecting the best Styrofoam shipping cooler in 2025, it's essential to consider a few key features that distinguish top brands and models. Look for coolers with superior insulation, which plays a critical role in maintaining temperature stability for perishable items. Some models feature multi-layer insulation technology that significantly extends ice retention time, offering an advantage for long-distance shipping. The overall design, including portability and ease of use, is also important—opt for coolers that come with built-in handles or lightweight materials for convenient transport.

Another factor to keep in mind is the size and capacity of the cooler. Different models cater to varying shipping needs, from small coolers ideal for individual packages to larger options designed for bulk shipping. Additionally, consider the durability of the cooler; thicker walls and reinforced construction can ensure that the cooler withstands the rigors of transportation while protecting its contents. With a variety of options available, focusing on these aspects will help you identify the ideal Styrofoam shipping cooler that meets your requirements for 2025.

The Ultimate Guide to Choosing the Best Styrofoam Shipping Cooler in 2025

This bar chart represents the performance ratings of various critical attributes of styrofoam shipping coolers for 2025. It provides insights into insulation quality, durability, size options, weight capacity, and price, allowing customers to make informed decisions when selecting a cooler.

Environmental Considerations in Styrofoam Cooler Selection

When selecting a styrofoam shipping cooler, one of the critical factors to consider is its environmental impact. Styrofoam, or expanded polystyrene (EPS), is notorious for its difficulty in recycling and decomposing. According to the American Chemistry Council, approximately 25% of EPS is recycled, leaving the vast majority in landfills, where it can take hundreds of years to break down. As the industry moves towards more sustainable practices, it becomes essential for consumers to choose coolers made from recyclable materials or those produced with environmentally friendly processes.

Tips for making an eco-friendly choice include looking for coolers labeled with recycling symbols or made from biodegradable materials. Additionally, consider the cooler's insulation efficiency, as better insulation can reduce the need for frequent replacement and minimize energy consumption. A report from the Environmental Protection Agency suggests that using high-efficiency insulated shipping solutions can cut down energy use and carbon footprint by up to 30%.

Finally, be mindful of the end-of-life handling of the cooler. Choosing a product that can be easily returned to the manufacturer for proper recycling or one that has a take-back program can significantly reduce environmental impact. Engaging with suppliers who are committed to sustainability helps promote a greener approach to shipping and packaging in the industry.

Tips for Proper Use and Maintenance of Styrofoam Coolers

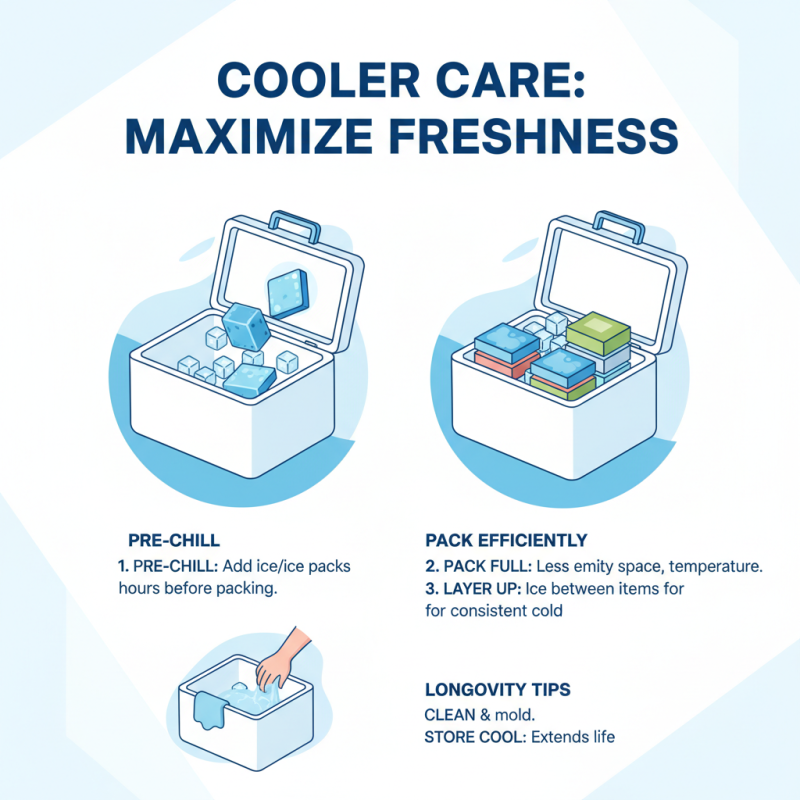

Proper use and maintenance of styrofoam shipping coolers are essential for ensuring their effectiveness and longevity. When using a styrofoam cooler, it’s important to pre-chill the cooler and its contents before packing. This can be accomplished by placing ice packs or ice in the cooler for a few hours prior to filling it with perishables. Additionally, packing the cooler efficiently is key; fill it to capacity, as a fuller cooler maintains temperature better. Always layer ice packs or ice in between items, as this helps to keep all contents at a consistent low temperature.

Maintenance of styrofoam coolers is straightforward but crucial for keeping them in good condition. After each use, ensure the cooler is thoroughly cleaned with mild soap and water to remove any residues and odors. Avoid harsh chemicals that can degrade the styrofoam material. Dry the cooler completely before storing it to prevent mold and mildew growth. Store the cooler in a cool, dry place away from sunlight, which can cause the styrofoam to break down over time. By taking these steps, one can extend the life of a styrofoam cooler and maintain its efficiency for future uses.

Related Posts

-

Mastering the Art of Packing with Styrofoam Shipping Boxes: A Step-by-Step Tutorial for Optimal Protection

-

10 Innovative Insulated Foam Cooler Designs To Keep Your Beverages Cold For Up To 36 Hours

-

How Insulated Shipping Coolers Enhance Food Safety and Reduce Waste in the Cold Chain Process

-

Unlocking the Benefits of Custom Insulated Boxes for Temperature-Sensitive Shipments

-

7 Best Innovations in Foam Shipping Coolers for Global Supply Chain Efficiency in 2023

-

Unique Examples of the Best Insulated Box for Every Industry